News

Catch up on the final SeaBioComp conference via video

The SeaBioComp final conference took place in Ostende 19th January 2023 with the theme; 'Bio-based Composites; are they a viable solution for the marine environment?'

The event was well attended with representatives from industry, academia, public authorities, the bio-composite supply chain and major stakeholders.

To catch up on the presentations from the event follow the link to see the event video.

https://www.youtube.com/watch?v=vRBDiBBy2oY

Posted 2023-02-07 09:50:44

SeaBioComp project develops demonstrator products from biocomposites for marine applications

SeaBioComp has successfully produced a number of demonstrator products for the marine environment, using different manufacturing processes, to showcase its flax based thermoplastic biocomposites.

Project partners in the team, including research organisations, textile and composite specialists, universities, and cluster organisations, have been working together for the past 3 years to develop, mechanically test and research a number of biobased formulations using different manufacturing techniques.

Two different kinds of biocomposites have been developed by the consortium; a self-reinforced PLA-composite which has been made into a variety of non-woven and woven fabrics suitable for use in compression moulding, and a flax reinforced polylactide (PLA) or acrylic (PMMA) reinforced composite for use via RIFT, compression moulding and additive manufacturing.

Extensive testing of the mechanical properties of the various bio-composites has concluded that these materials are close to and in some instances perform better than conventional non-bio-based composites (sheet moulded composite, SMC) currently in use in the marine environment today. The new bio-based products have been shown to use the same compression moulding conditions as conventional products and sometimes the process cycle time, can be shorter.

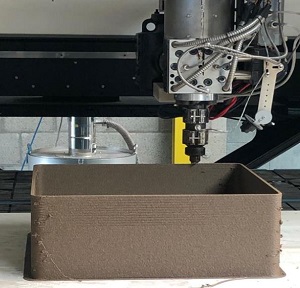

The project has shown that the combination of thermoplastic polymers, natural fibres and 3D printing technologies can result in technically complex designs and applications being produced for the marine environment. A number of initial prototype products, including a fender and other port structures have successfully been produced using 3D printing; scale model offshore wind turbine blades manufactured via monomer infusion under flexible tooling (MIFT) and complex curved structures using compression moulding techniques

.

The project has released a series of technical leaflets detailing the various production methods using self-reinforced biocomposites and flax based biocomposites for marine applications, including compression moulding, monomer infusion and additive manufacturing. These technical leaflets will be of interest to manufacturers of marine products as well as supply chain companies and the academic sector and are available as downloads from the project website: http://www.seabiocomp.eu/downloads/

In addition, the project has also determined whether these bio-based self-reinforced polylactic acid (SRPLA) products are suitable for use in the marine environment from a durability and microplastic formation perspective. A new paper, published in Polymer Testing, Science Direct discusses the potential for SRPLA to be considered a promising material for sustainable marine applications. https://www.sciencedirect.com/science/article/pii/S0142941822001441

The motivation for the project is to reduce the use of fossil-based materials in the marine sector by developing bio-based composites that have long-term durability with reduced CO2 emissions and environmental impact on the marine ecosystem. Early research in the project identified flax as the most suitable natural plant fibre to be used as reinforcement in the bio composite. During growth, flax absorbs a lot of CO2 and 'cleans' the soil through phytoremediation.

Posted 2022-07-27 12:30:03

SeaBioComp partners publish paper on 'Behaviour of a self-reinforced polylactic acid (SRPLA) in seawater

A number of SeaBioComp partners have collaborated to get this paper on the 'Behaviour of SRPLA in seawater' published in Science Direct.

The goal of the study was to determine whether a bio-based self-reinforced polylactic acid (SRPLA) is suitable for use in structures deployed in the marine environment.

The highlights from the paper include:

* New test results are shown for seawater aging of SRPLA for up to 24 months' immersion.

* Correlation established between water ingress and property loss.

* Tensile and impact test results show PLA ductility can be improved by self-reinforcement.

* Study of microplastic formation in seawater with and without UV exposure.

The material was produced from co-mingled fibres with different melting points. Two key criteria, durability during service and microplastic formation, were examined.

To assess durability, mechanical properties, tension and transverse impact, were used to quantify the influence of seawater ageing for up to 24 months. After seawater ageing at 40 °C for 12 months, composite strength was completely degraded.

To assess microplastic formation, specimens of SRPLA were exposed in seawater to accelerated ultraviolet (UV) radiation simulating natural exposure for up to 18 months.

Fluorescence microscopy and infrared technology were used to quantify and characterise the microplastics formed. Their number was independent of UV exposure, suggesting short-term UV radiation does not accelerate SRPLA microplastic formation.

The paper discusses the potential for SRPLA to be considered a promising material for sustainable marine applications.

For more information and to download the article please follow the link:

https://www.sciencedirect.com/science/article/pii/S0142941822001441

Posted 2022-06-17 11:45:10

SeaBioComp project produces technical leaflets on use of flax reinforced composites in various moulding techniques

The SeaBioComp project has produced a series of technical leaflets detailing the various methods of using flax based biocomposites for marine applications.

Project partners in the team have been working together for the past 3 years to develop, mechanically test and research a number of biobased formulations using different manufacturing techniques.

The result is the release of four technical documents that explain:

* Self-reinforced biocomposites in compression moulding

* Self-reinforced flax biocomposites in monomer infusion

* Self-reinforced flax biocomposites in compression moulding

* Self-reinforced flax biocomposite in additive manufacturing

In addition the project has been looking at the microplastic and ecotoxicity effects of biopolymers and biocomposites.

All the technical documents are available to view and download on the SeaBioComp website at http://www.seabiocomp.eu/downloads/

Posted 2022-05-17 10:56:14

Watch the video of 'The Future of Biobased Polymer and Natural Fibre Composites for the Marine Environment' event

Anyone who missed 'The Future of Biobased Polymer and Natural Fibre Composites for the Marine Environment' event which took place in Tourcoing in France recently can catch up with all the presentations by watching the video of the event.

Project partner EuraMaterials hosted the event which included a tour of another project partner, CETI in Tourcoing in France in April 2022.

The speakers at the event included a mix of project partners, to give an overview of the project, its activities and findings to date, as well as some speakers from industry talking about biocomposites from the marine industry perspective.

88 delegates registered to attend the event, either online or in-person, from a number of European countries.

A video of the event can be viewed at the following link:

https://euramaterials.eu/revoir-levenement-seabiocomp-sur-les-composites-thermoplastiques-biosources-innovants/

Posted 2022-06-08 12:15:12

CETI hosts tour of its innovative facilities

Project partner CETI, The European Centre for Innovative Textiles, recently open their doors to delegates at the SeaBioComp event in Tourcoing in France.

The tour of CETI's facilities was extremely interesting with delegates being shown the company's state-of-the-art technologies as well as learning about their innovative equipment and capabilities which develop new textile applications.

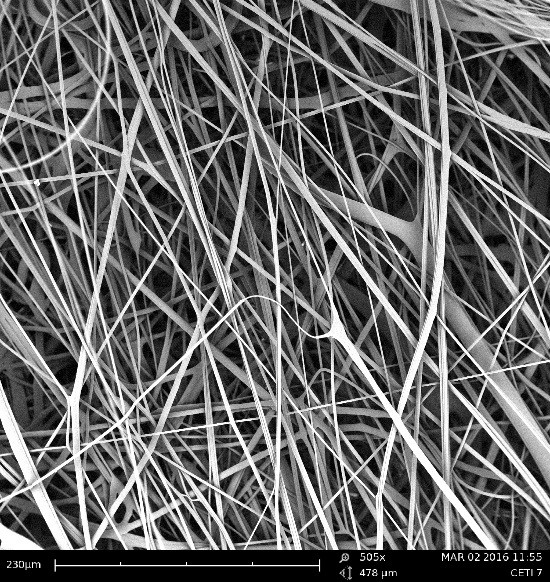

CETI have produced a flax bio-polymer nonwoven as part of the SeaBioComp project.

Posted 2022-06-08 12:22:45

Harbour mooring product produced from Flax/PLA as demonstrator example

SeaBioComp partner Poly Products has been proactively seeking out harbour products to produce from the bio-composites developed by the project to use as demonstrator examples for businesses to see practical applications of the project's work.

Albert ten Busschen and Michiel de Bruijcker from Poly Products came across a boat protection item that was at the end of its life and decided to design a new alternative that could be 3D printed on their machine using the flax/PLA material that Centexbel has made for the SeaBioComp project.

Two parts were designed, the 'boat protector' and a 'top cover' which acts as a protection cover again rain and sea water ingress. Poly Products used the FGF 3D printing technology process to shape the products.

The completed product, once installed in the correct place in the harbour will prevent damage to vessels and boats navigating or mooring close to the bollards.

If your business has an idea for a demonstrator product to be made from the bio-composite materials developed by the SeaBioComp project please get in touch with the project manager, ids@centexbel.be

Posted 2021-11-24 10:22:34

New report on ecotoxicity effects due to biopolymers and fossil fuel based products in the marine enviroment available to download

For this latest report, the SeaBioComp project has assessed and compared the effect of leachate from a biocomposite and leachate from a fossil-fuel polymer in the marine environment.

The dependence of fossil fuel-based polymers in human society has led to a series of environmental issues, such as accumulation of plastic debris. Polymers made from a natural-sourced feedstock, like polylactic acid (PLA) and thermoplastic starch (TPS), known as biocomposites, are seen as potential alternatives.

However, concerns are emerging as to whether these biocomposites have a lower ecological impact than fossil-fuel based polymers. In the marine environment, plastic additives can be released, i.e. can leach, from plastic to the surrounding seawater and organisms. Studies have demonstrated the negative effects of leachate from several fossil fuel-based polymers on marine organisms, however, to date, few studies have assessed the potential effect of leachate from biocomposites.

To read the full report please go to the downloads section of the website at the following link: http://www.seabiocomp.eu/downloads/ where you can access this latest report; SeaBioComp_D3.3.2 Report on ecotoxicity effects due to biopolymers.pdf

Posted 2021-12-14 15:01:55

Flax/Acrylic demonstrator wind turbine blade produced as part of SeaBioComp project

The University of Plymouth, one of the project partners in the SeaBioComp project, has produced a flax reinforced acrylic thermoplastic scale model of a wind turbine blade as a demonstrator component for the project.

The two half blades (front and back) were manufactured using a flax fabric reinforced acrylic thermoplastic matrix by in situ polymerisation monomer infusion techniques under flexible tooling (MIFT).

The mould profile is for a floating offshore wind (FLOW) turbine blade at a scale of 1:50. The trimmed and faired blade weighs 395g.

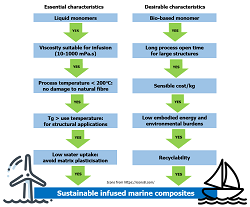

Large composite marine structures (eg boat hulls or wind turbine blades) are usually manufactured using a Resin Infusion under Flexible Tooling (RIFT) process. However there are few options for end-of-life disposal of these products in the recycling process.

The SeaBioComp project is seeking to develop in situ polymerisation (ISP) of bio composite materials using the Monomer Infustion under Flexible Tooling (MIFT) method.

For more information on the project and its findings please visit http://www.seabiocomp.eu/

Posted 2022-02-03 15:37:20

Call for suppliers and users of biocomposites to engage with SeaBioComp project

The SeaBioComp project is looking to engage with suppliers and end users of bio-composites; especially in the field of products for the marine environment.

The project is focusing on the supply chain aspects of biocomposites and is developing a commercialisation action plan for the development of bio-composite products in the marine environment.

In particular we are looking to make contact with potential stakeholders and suppliers in the production chain, initially companies interested in biocomposites for the maritime environment, made via compression moulding, additive manufacturing or monomer infusion using RIFT techniques. We are keen to engage with monomer/polymer, fibres, additives, compounding and filament/textile companies to better understand the market including quality, prices, delivery etc.

In addition we would like to make contact with contractors and customers like water management companies who are looking to use the new biocomposite technologies in order to fully understand their requirements and cost implications.

This study into the value chain for biocomposites in marine applications will enable the project to produce some practical flyers to highlight the project demonstrators and their advantages compared to traditional materials, to identify innovations that are required and to list potential products of the future for example the use of biocomposites in areas such as ports and harbours.

To get more information on the specifications of the various biocomposite materials being developed by the SeaBioComp project please download the specification sheets available in the downloads section of the website; Flax/PLA/COPLA specification and self reinforced PLA composite.

http://www.seabiocomp.eu/downloads/

Anyone wishing to be involved in these discussions can contact us via Leon Joore welcome@natuurvezelapplicatiecentrum.eu , Isabel De Schrijver ids@centexbel.be and Elke Demeyer edm@vkc.be

Posted 2021-09-15 12:12:04

Updated Assessment of the microplastic formation and toxicity of biobased composites 2021

Project partner VLIZ has updated their assessment of the microplastic formation and toxicity of biobased composites in a new paper which is available to download from our website.

The new findings were recently presented at the 52nd Liege Colloquium on Ocean Dynamics in May 2021.

The goal for SeaBioComp is to produce a new biocomposite for marine applications. The VLIZ research has assessed microplastics formation under sunlight exposure and also assessed the ecotoxicological effects of leaching substrates.

The results are available to download at the following link as well as a number of other results from the SeaBioComp project.

http://www.seabiocomp.eu/downloads/

Posted 2021-06-09 11:18:07

New download available on the Microplastic formation from a newly developed biocomposite

SeaBioComp partner VLIZ recently presented a poster at the 3rd Biannual MICRO2020 conference which is available to download from the following link: http://www.seabiocomp.eu/downloads/

The Poster details the Microplastic formation from a newly developed biocomposite which has been produced as part of the SeaBioComp project.

The poster details the comparison of Microplastic formation on the new biocomposite compared to a fossil-based polymer during their degradation under UV radiation.

The results of the research will contribute to assessing the risk of biocomposites which can present a more sustainable alternative to fossil-based polymers.

Posted 2021-06-09 11:06:20

Developing high quality biocomposite materials with reduced environmental impacts

Work Package 1 of the SeaBioComp project is looking to develop high quality biocomposite demonstrators which will have a significantly reduced environmental impact compared to traditional oil-based composites.

Thermoplastic polymers are interesting matrix materials due to their high-strength-to-weight ratio, processability, low production costs and high corrosion resistance properties.

In general, oil-based thermoplastics are not biodegradable and the recycling at the end of their lifetime is still a difficult and expensive task, even if it is theoretically feasible.

Hence, some bio-thermoplastics which are biodegradable, are being widely investigated as ecofriendly alternatives to conventional oil-based thermoplastics.

One of the main drawbacks of biobased thermoplastics such as PLA (Poly Lactic Acid) is their low mechanical properties, in particular low toughness. The SeaBioComp project aims to develop 100% biodegradable (or recyclable) thermoplastic composites while addressing the issue of low mechanical performance such as toughness of common biobased polymers.

A great deal of work between partners and material suppliers has gone into producing a number of different bio composite materials including:

* Self-reinforced biopolymers with low melting temperatures biopolymers in the matrix and high melting bioploymers in the reinforcement material

* Hybrid composite materials of flax fibres and biopolymers

* Thermoplastic monomer injection flax fibre preforms

The first year of the project was spent learning about the various materials and their properties; this second year has seen partners working on specific materials to give workable results for the industry.

These materials are now being optimised through adaptations, testing and manufacturing procedures.

In August tests were carried out on high and low melt grade bio-polymer fibres, filaments and non woven samples using melt spinning and melt blown processes. Optimised results are emerging but testing is on-going with more results due in the New Year on multi-filament and combination matrix materials.

Early indications demonstrate that in order to optimise the mechanical properties of filaments and non-woven materials, it is both the selection of the polymer reinforcement and the polymer matrix that is important. The adhesion between the reinforcement and material matrix is also recognised as being very important in getting optimal results.

A number of material combinations are looking promising and will be tested for ageing and marine applications.

This work package will be testing the processability of these materials and will be developing prototypes of bio component and bio based multifilaments and spunbond nonwovens using different polymers.

Posted 2020-11-18 15:55:23

Analytical protocols for bio-composites

Work Package 3 of the SeaBioComp project has seen project partners University of Portsmouth, VLIZ and Ifremer developing analytical protocols to test the bio-composite materials.

The team are working on the long-term durability of the materials through testing in simulated and real-life seawater as well as ecotoxilogical effects including leachates and microplastic formation.

The results of these tests and protocols will enable life-cycle analyses to be put together for the various materials.

Posted 2020-12-07 18:34:24

Natural Fibre Research and Selection for the project completed

Partners CETI and Centexbel have been investigating and evaluating the many natural fibres that can be used for manufacturing natural fibre composites.

The interest in natural fibres composites is growing rapidly due to their potential to replace synthetic fibre composites at lower cost and lower environmental impact. In addition natural fibres are a renewable resource for which production requires generally less energy compared to synthetic fibres. Many natural fibres can be used for the manufacturing of natural fibre composites and these were tested and evaluated as part of the SeaBioComp project.

The choice of the natural fibre in the composite is very important because the fibre used for reinforcement will directly affect the properties of the composite including elongation, strength and Young’s modulus. The main disadvantages of using natural fibres in the reinforcement of composites is the low thermal stability during fabrication and poor compatibility between fibre and matrix.

The SeaBioComp project has undertaken important research in order to give an overview of the different natural fibres available and of the different treatments which can be used to improve the interphase between fibres and matrix.

As a result of this work, two natural fibres have been selected (according to their environmental impact, cost, properties and availability) which will be used in the SeaBioComp project to manufacture pilot products. Flax and hemp were selected as the most suitable fibres to be used, due to a combination of their availability in Europe, mechanical properties, price and environmental impacts.

In the research, it was demonstrated that the level of retting is important and should be discussed with the supplier during purchasing. A high degree of retting enables easier splitting of the fibre bundles during fibre / matrix extrusion and injection moulding. This involves an increase of the mechanical properties with the degree of retting for both Young’s modulus and strength at breaking point.

The project research shows that it is necessary to improve the interface between fibre and matrix. Reinforcing fibres can be modified by physical, chemical or biological methods. Chemical treatments (such as alkali) are the most commonly used. Biological treatment (using enzymes) is becoming increasingly popular and offers particular benefit relating to environmental friendliness.

By making natural composite products using plant-based natural fibres as a reinforcement and biodegradable polymers as matrices, the project hopes that the ecological impact will be more than half compared to oil-based composites in addition to a 30 per cent reduction of CO2 emissions from their production.

Posted 2020-05-01 13:37:02

Investigating mechanical, physical and environmental properties of biopolymers and biocomposites

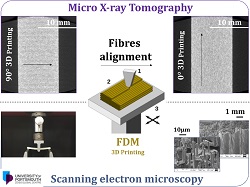

Work Package 3 of the project has been investigating the mechanical, physical and environmental properties of biopolymers and the biocomposite materials produced by other project partners in SeaBioComp using compression moulding and additive manufacturing techniques.

The relationship between different process parameters and material types and the different properties of the 3D printed and compression moulded biocomposites have been evaluated by the University of Portsmouth and French partner Ifremer.

The materials tested include TPS-OPT (Optimized Thermoplastic Starch) which is a biodegradable matrix and PLA (Poly Lactic Acid) which comes from renewable resources and is biodegradable and has high mechanical properties.

These biocomposites have been tested with different reinforcements including carbon and glass fibres as reference materials along with hemp, flax and new core-shell fibres developed for the project.

Quasi-static and dynamic experiments such as tensile, three-point bending and drop weight impact tests were carried out. Moisture absorption behaviour and its influence on various properties was evaluated by immersing the biocomposites in seawater conditions at different temperatures. Density measurement as well as Differential Scanning Calorimetry (DSC) were also undertaken to evaluate the long-term effects of sea water ageing.

In addition, as mechanical and physical properties of biocomposites are correlated to degradation at the fibre/matrix interface, manufacturing defects as well as overall damage mechanisms of the composites were analysed using destructive and non-destructive characterisation techniques. In this regard, cutting edge technology, such as Scanning Electron Microscopy (SEM) and micro x-ray tomography (XCT) was employed, which show visual and numerical information above and beneath probed sample surfaces, determining the origin of critical defects due to manufacturing or developing over the long-term within harsh environments present in the marine environment.

The results from the testing will be fed back into the next phase of the material development for the SeaBioComp project.

Posted 2020-12-07 18:47:16

Call for ideas for demonstrators of biobased composites for the marine environment

The SeaBioComp project aims to build demonstrator products for marine applications from bio-based, thermoplastic composite material.

The project partners are encouraging companies to share ideas for possible demonstrator products. Objects up to 2 meters in diameter can be printed with 3D technology.

The SeaBioComp project aims to develop demonstrator products from bio-based composites that can potentially replace the traditional fiber-reinforced composites used in the marine and maritime industry.

The bio-based composite must have at least the same mechanical properties, achieve a suitable service life (depending on the application) and reduce both CO2 emissions and ecotoxicity by 30 % and 50 % respectively. Because thermoplastic composites are used, the recycling process will also be studied in more detail and used to finalise the protocol.

The demonstrator products and analytical protocols that the project will deliver will hopefully convince the marine and maritime industries that bio-based composites can offer a realistic and feasible alternative to less sustainable materials.

The consortium is therefore launching a call to the marine industry to propose possible applications of bio-based composites in an offshore environment. The consortium will then determine which proposed demonstrator product can be built.

Possible demonstrator items could include marine products such as fishing gear, boats, floating structures (e.g. buoys, floaters) and infrastructure components (e.g. ships, anchors) from different areas of the blue economy (aquaculture, offshore energy, shipping, coastal defense, tourism).

Do you have an idea for a possible application? Please contact us at ids@centexbel.be with your proposal for a demonstrator product.

If you are interested to be kept up to date with the project and its outcomes please sign up to the Interest Group at http://www.seabiocomp.eu/interest_group/

Posted 2020-12-14 13:44:42

SeaBioComp Masterclass on 3D printing of Biopolymers stimulates lively interaction

2020/21 has required new ways to connect with businesses, stakeholders and interested parties in order to disseminate project results.

In September 2020, Dr Albert ten Busschen, from Poly Products, hosted a very successful online MasterClass titled 'Large-scale 3D printing of Biopolymers'.

The event successfully informed interested parties of the activities of Work Package 2 and all the activities associated with 3D printing of bio-polymers. The event attracted an audience of 14 delegates from a good cross section of industry and research organisations.

SeaBioComp project leader Gertjan Vancollie also presented during the MasterClass, giving an overview of the SeaBioComp project, its aims and ambitions and project findings and research to date.

The MasterClass was obviously of interest to the participants who asked many questions which will prove very valuable to the future research being undertaken by the SeaBioComp project. The event proved to be efficient, lively and interactive despite being held online due to Covid-19.

Presentations from both the presenters can are available to download from the following link: http://www.seabiocomp.eu/downloads/

In addition some useful reports are available to download including the SeaBioComp 3D-printed fender report and the report on the Adaptations needed to print biopolymers on 3D printers.

All downloads are available from: http://www.seabiocomp.eu/downloads/

Posted 2020-09-22 11:04:42

Assessment of degradability and toxicity of biobased composites available to download

Information on the work being undertaken by project parnter VLIZ on the assessment of the biodegradability and toxicity of biobased composites as part of the SeaBioComp project is now available in a download.

The poster was presented at the 2020 SETAC Annual Meeting.

To download your copy please visit: http://www.seabiocomp.eu/downloads/

Posted 2020-06-18 10:07:36

Designs and tests of 3D printed biopolymer fender available to download

A report into the first designs and tests of 3D printed biopolymer fenders is now available to download from the SeaBioComp project.

Please visit http://www.seabiocomp.eu/downloads/ to obtain your copy.

Posted 2020-06-18 10:02:36

Report into the adaptations for 3D printing of biocomposites available to download

The report into the adaptations required for 3D printing of biocomposites is now available to download from the SeaBioComp project.

The report describes the adaptations that are necessary for the processing of biopolymers in 3D printing.

Please visit http://www.seabiocomp.eu/downloads/ to obtain your copy of the report.

Posted 2020-06-18 09:59:23

3D Printer produces first bio-polymer concept product for the marine sector

SeaBioComp has produced its first 3D printed biopolymer fender profile for use in the marine environment.

The fender profile was printed on an FDM Printer by Poly Products, a Netherlands based composite production and specialist engineering business, and partner in the SeaBioComp project, in collaboration with de Klerk Waterbouw who specialise in the installation of products for the marine environment.

SeaBioComp funded the research into the adaptations required to enable the 3D printing machine to process biopolymers which was undertaken by Poly Products. Research and testing into temperature control, natural fibre selection and corrosion of extruder parts were all thoroughly reviewed.

Project observer partner, De Klerk Waterbouw wanted to investigate the design and production of a bio-composite vertical fender profile for the berthing and guiding of ships, in order to replace traditionally used tropical hard woods and synthetic plastics. Collaboration with industry, end users, research establishments and public authorities is a key part of the SeaBioComp project, so a number of partners worked on the design, material selection, 3D printing, testing and evaluation of a scaled version of the biopolymer fender profile.

The findings from the material testing led by the University of Portsmouth and mechanical testing by De Klerk Waterbouw show very promising results and further optimization of designs, materials and production may lead to future full-scale production.

Commenting on the success of the 3D printing, Dr Albert ten Busschen, Poly Products, said: 'Using our 3D-printing technique, products can be made directly without the need of a mould. This saves the use of material and time. Moreover, there is no material spillage when a product is produced because no trimming or machining is necessary. Within the SeaBioComp project it is important that biopolymers can be printed with our 3D-printer. We printed the biobased polymers Thermoplastic Starch (TPS) and Poly Lactic Acid (PLA) on our machine to prove that we can make sustainable products for marine applications. Together with De Klerk we are now pursuing the development of full-scale fender profiles printed with biopolymers. We have completed mechanical tests and are now planning to print and install a full-scale printed fender profile with De Klerk to see how it works in practise.'

Ivo van Dalen, technical project leader of De Klerk Waterbouw is very enthusiastic: 'De Klerk Waterbouw has installed hydraulic engineering structures for over 150 years. We make large structures in docks and harbours from traditional materials like steel and tropical hardwood. But we are always open to new innovations and feel the responsibility to support a sustainable society. The SeaBioComp project opens possibilities for our company to make developments in that direction. The cooperation with Poly Products is very productive: we have jointly developed new, efficient and biobased fender profiles for berthing structures. With the production of full-scale prototype profiles we will undertake practical tests on the quay at our premises. Both our companies are oriented to develop solutions that are practical and efficient.'

The reports into the adaptations required for 3D printing of biocomposites and details of the 3D printed fender are available as downloads from the website. http://www.seabiocomp.eu/downloads/

Posted 2020-04-30 11:03:36

New findings from FLOWER Interreg project developing flax fibres reinforcements

The FLOWER Interreg project is aiming to develop flax fibre reinforcements for the composite industry at lower costs.

The project is hoping to use sustainable, cost effective and environmentally friendly lightweight composites as a viable alternative for automotive, advertising and sailing sectors which makes it of interest to the SeaBioComp project.

The project has recently published a paper on the 'Monitoring of mechanical performances of flax non-woven biocomposites during a home compost degradation'. The paper is available to view at the following link:

https://www.sciencedirect.com/science/article/pii/S0141391020300987?via%3Dihub

The University of Portsmouth is one of the partners in both the FLOWER project and SeaBioComp.

Led by the University of South Brittany, FLOWER brings together 4 academic partners (University of South Brittany in Lorient, INRA in Nantes, University of Cambridge and University of Portsmouth) and 4 industrial partners (the companies Kaďros, Teillage Vandecandelačre, EcoTechnilin and Howa-Tramico) located on both sides of the English Channel.

For more information please visit http://flower-project.eu/?lang=en

Posted 2020-05-11 18:25:12

Encourage colleagues and contacts to join the SeaBioComp Interest Group

The SeaBioComp Interest Group will be sending out regular updates, details of events and project activities and results from the project.

Make sure your colleagues, relevant contacts and network are signed up to the interest group in order to be kept up to date with the project and its findings.

Follow the link to sign up:

http://www.seabiocomp.eu/interest_group/

Posted 2020-04-29 17:02:14

Early project findings and deliverables

A number of early project deliverables have already been completed including a comprehensive report from project partner CETI assessing the natural fibres that could viably be used in bio-composites.

The report concludes that flax and hemp will be selected for future study in the project on the basis of mechanical properties, price & environmental impacts.

Project partner Plymouth University has been reviewing available thermoplastic monomers suitable for resin infusion under flexible tooling (RIFT) for marine applications and has made a recommendation for the project.

Meanwhile the University of Portsmouth has been testing the mechanical and durability properties of flax and flax PLA fabricated using 3D printed composites by Dutch partner Poly Products who are experts in fibre reinforced composite production and engineering.

Posted 2020-03-13 14:00:11

Monomer selection for in situ polymerization infusion

The SeaBioComp project is looking to develop and deliver demonstrators using innovative bio-based thermoplastic composite materials with mechanical properties comparable to conventional oil-based composites.

The durability will be tailored to the specific application (2 to >20 years), recycling potential, reduced CO2 emissions and reduced microplastic and ecotoxic impact in the marine environment.

The University of Plymouth, as part of its role in the project, is investigating to use of manufacture by monomer infusion under flexible tooling (MIFT) with in situ polymerisation to produce natural, or glass, fibre reinforced structural composites.

Following an extensive literature survey, the monomer selection has suggested two potential matrix materials: poly(methyl methacrylate) (PMMA) and poly(L-lactide) (PLA). The selection methodology is described in a paper just published in Polymers.

The full report is available to view at the following link.

https://www.mdpi.com/2073-4360/12/12/2928

and also available to download from the SeaBioComp website at http://www.seabiocomp.eu/downloads/

Posted 2020-11-18 16:27:31

Sign up to the SeaBioComp online Interest Group if you are interested in bio-based composite alternatives for the marine industry

SeaBioComp, the new collaborative project developing and producing novel bio-based thermoplastic composite materials for the marine sector, has launched its new website and online Interest Group.

The aim of the website is to disseminate information, updates, achievements and downloads throughout the project. Interested businesses, academia, public authorities, stakeholders and media are asked to subscribe to the Interest Group in order to be kept informed of the project activities and findings and receive invitations to relevant events and forums.

Anyone interested in this important and growing area of bio-based materials for the marine environment is invited to join the Interest Group at http://www.seabiocomp.eu/interest_group/

Subscribers to the Interest Group will be kept informed of relevant events and forums, project activities, results etc. The aim of the Interest Group is to stimulate inclusive engagement of external stakeholders and interested parties including the triple helix of academia, industry and public authorities.

Posted 2019-09-27 10:00:14

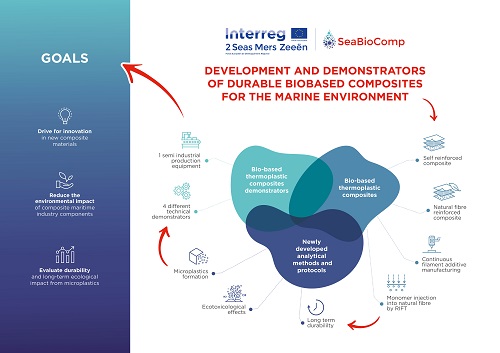

SeaBioComp infographic available to download

SeaBioComp has designed an infographic to describe the project in a simple and clear format. The graphic, which has been created by project partner EuraMaterials, depicts the aims and objectives of the project in pictures to enable quick and easy understanding of what the project will deliver.

The SeaBioComp Infographic is available to download by following the link:

http://www.seabiocomp.eu/downloads/

Please attribute the Infographic to the SeaBioComp project.

Posted 2019-10-09 11:52:11

SeaBioComp project launched to tackle the use of harmful oil-based composites in the marine environment.

SeaBioComp is a new collaborative project that has been launched to develop and produce novel bio-based thermoplastic composite materials and the analytical protocols to evaluate long-term durability and reduced ecological impact on the marine environment.

SeaBioComp held a successful kick-off meeting in Lille in April 2019 bringing together all 11 partners from the 2Seas region covering the coastal regions along the southern North Sea and Channel area including 4 EU-member states: England, France the Netherlands and Belgium.

Posted 2019-06-25 15:53:19 by Admin

Promising mechanical testing results for new biocomposite materials developed by SeaBioComp

Even if conventional natural fiber reinforced polymer composites show equivalent mechanical properties and lightweight performance compared to glass fiber reinforced composites; in terms of stiffness, viz. specific stiffness (the ratio of Young's modulus to density), their low strength has been a technical barrier for their widespread adoption in different industrial sectors.

In particular, the brittleness of flax fibers and biopolymers such as PLA has been a main drawback of such materials. In the SeaBioComp project, we have developed a new composite system by implementing two different reinforcements, i.e. flax fibers and PLA fibers, into a coPLA matrix.

While flax fibers bring the stiffness, ductile PLA fibers can enhance the strength and reduce the weight of the composite materials owing to its low density.

From the mechnical test results, it has been proven that the specific strength (i.e. the ratio of strength to density) of this new biocomposite material is equivalent with that of sheet moulding compound (SMC) which is currently one of the most popular composite materials, whereas its specific stiffness is superior to that of SMC.

Moreover, even a complex part with a stiffener can be manufactured without wrinkles by the conventional compression molding of a dry fabric preform whose processing temperature is the same as that of SMC compression moulding.

Another advantage is that the storage life time is almost infinite whereas thermoset-based composites such as SMC should be conserved at a low temperature within a limited duration.

Among some potential industrial applications is a skim-board which has been fabricated by hand-layup of thermoset resin and fibers using a process that is labour intensive and using materials that have heavy carbon footprints.

A scientific paper is being prepared to present the results of this development and will be reported via this website in 2022.

More information about the specific characteristics of the materials being developed by the SeaBioComp project can be downloaded from the website at the following link: http://www.seabiocomp.eu/downloads/