Investigating mechanical, physical and environmental properties of biopolymers and biocomposites

Work Package 3 of the project has been investigating the mechanical, physical and environmental properties of biopolymers and the biocomposite materials produced by other project partners in SeaBioComp using compression moulding and additive manufacturing techniques.

The relationship between different process parameters and material types and the different properties of the 3D printed and compression moulded biocomposites have been evaluated by the University of Portsmouth and French partner Ifremer.

The materials tested include TPS-OPT (Optimized Thermoplastic Starch) which is a biodegradable matrix and PLA (Poly Lactic Acid) which comes from renewable resources and is biodegradable and has high mechanical properties.

These biocomposites have been tested with different reinforcements including carbon and glass fibres as reference materials along with hemp, flax and new core-shell fibres developed for the project.

Quasi-static and dynamic experiments such as tensile, three-point bending and drop weight impact tests were carried out. Moisture absorption behaviour and its influence on various properties was evaluated by immersing the biocomposites in seawater conditions at different temperatures. Density measurement as well as Differential Scanning Calorimetry (DSC) were also undertaken to evaluate the long-term effects of sea water ageing.

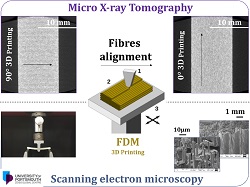

In addition, as mechanical and physical properties of biocomposites are correlated to degradation at the fibre/matrix interface, manufacturing defects as well as overall damage mechanisms of the composites were analysed using destructive and non-destructive characterisation techniques. In this regard, cutting edge technology, such as Scanning Electron Microscopy (SEM) and micro x-ray tomography (XCT) was employed, which show visual and numerical information above and beneath probed sample surfaces, determining the origin of critical defects due to manufacturing or developing over the long-term within harsh environments present in the marine environment.

The results from the testing will be fed back into the next phase of the material development for the SeaBioComp project.

Send this story to a colleague

Send this story to a colleague